Human-Centered Design

Written by

Sandeep Ozarde

Written by

Sandeep Ozarde

Human-Centered Design

Industry 5.0 is fundamentally reshaping this paradigm by emphasizing people over technology. Industry 5.0 is possible as a result of a focus on research and innovation, as well as by prioritizing technology in the transition.

Industry 5.0 addresses real-world issues. Industry 5.0 has the potential to address a variety of issues, including pollution, health care, sustainable production, energy consumption, and governance. Human creativity is required for Industry 5.0: problems can be solved by humans or robots. To achieve optimal performance, Industry 5.0 assumes that people must be at the intersection of technology, process, and design.

Japan’s new blueprint for a super-smart society, Society 5.0, is a more far-reaching concept than the Fourth Industrial Revolution, for it envisions completely transforming the Japanese way of life by blurring the frontier between cyberspace and physical space. Here, the author of the chapter on Japan in the last UNESCO Science Report (2015), Professor Yasushi Sato from Niigata University, explains why both the government and business leaders have high hopes for this strategy.

Former Japanese PM Shinzo Abe has sought to revitalize Japan’s economy by promoting ‘Abenomics’, which consists of ‘three arrows’: 1. monetary easing, 2. fiscal stimulus, and 3. a growth strategy

These arrows were analyzed by the UNESCO Science Report: in 2030. The first two arrows have helped Japan’s economy to stay afloat but it is the last component that will be all-important in the long run. After the Abe Cabinet issued its first growth strategy in 2013, this was revised every year until 2017, when it was overhauled to include the new concept of ‘Society 5.0’.

The term refers to the idea that Society 5.0 will follow Society 1.0 (hunter-gatherer), Society 2.0 (agricultural), Society 3.0 (industrialized), and Society 4.0 (information). Also called the ‘super-smart society’, Society 5.0 envisions a sustainable, inclusive socio-economic system, powered by digital technologies such as big data analytics, artificial intelligence (AI), the Internet of Things, and robotics. The ‘cyber-physical system’, in which cyberspace and the physical space are tightly integrated, becomes a pervasive technological mode supporting Society 5.0. To some, the concept sounded like a lofty vision at first, with no clear prospect of how it would unfold. Today, it inspires enthusiasm.

In Society 5.0, any product or service will be optimally delivered to people and tailored to their needs. At the same time, Society 5.0 will help to overcome chronic social challenges such as an ageing population, social polarization, depopulation, and constraints related to energy and the environment.

Japan’s Artificial Intelligence Technology Strategy is a key pillar of Society 5.0. It characterizes AI as a service and foresees three phases for AI development and use: (1) expanding use of data-driven AI in each service domain, (2) general use of AI and data across services, and (3) the formation of ecosystems through a complex merger of these services. The Artificial Intelligence Technology Strategy applies this framework to three priority areas of Society 5.0, namely health, mobility, and productivity.

We have lived through three industrial revolutions. The majority of people are currently experiencing the fourth. There were 100 years between the first three revolutions. It only took about 40 years to advance from the third to the fourth position. It is possible that reaching the fifth one will take less than 40 years.

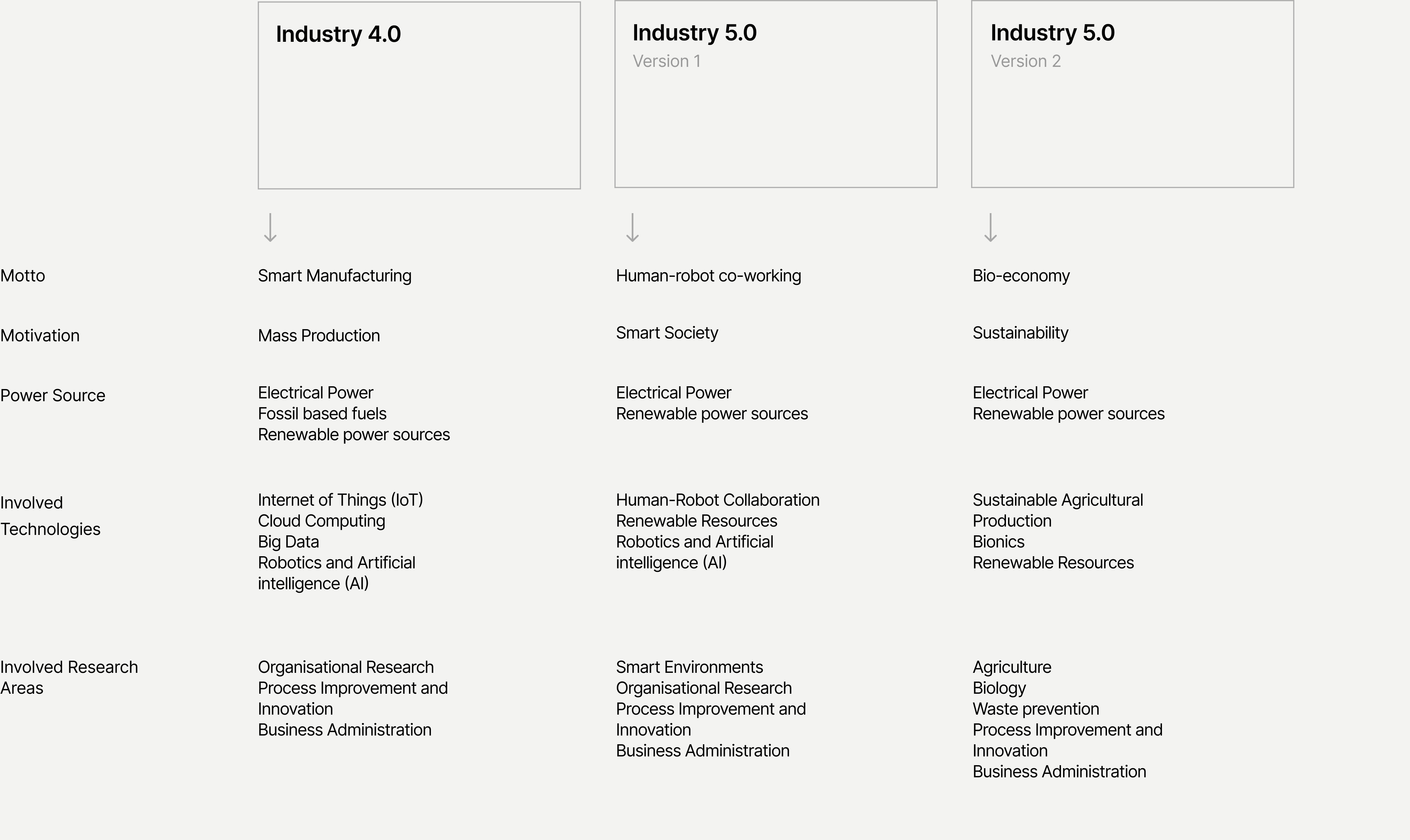

Table 1. Industry 5.0 and Human-Robot Co-working by Kadir Alpaslan Demira, Gözde Dövena, Bülent Sezenb. Published by ELSEVIER.

Innovative solutions that are valuable to users, gain a competitive edge, and are environmentally and socially responsible are developed through human-centered design. The success of any innovative design solution is contingent upon a human-centered approach to design and development. Human-centered design is a method for solving problems creatively while developing products and services that are centered on people.

To make things more sustainable, we need to take advantage of Industry 4.0 s technological potential by adopting Industry 5.0 s human-centered goals. Industry 5.0 strengthens industries' resilience and adaptability by developing human-centered innovative technologies that enable and empower workers rather than replacing them. As a result, it s not just a matter of developing new technologies; it s also a matter of figuring out new ways to put them to use to build a more humane society. With Industry 5.0, we're starting to see how important it is to combine human creativity with machine precision and reliability.

Manufacturers will be able to use agile and human-centered design methods to iteratively implement Industry 4.0 technologies with their direct stakeholders. Without a doubt, to develop next-generation industrial solutions, leaders in this turbulent era must combine these two approaches. Manufacturers will be disrupted by Industry 4.0 s transformation through the application of new technologies, products, services, and business models.

While there are many new ways for people and technology to interact as a result of business transformation, industry, and research stakeholders are still unsure what fully digitized production and logistics systems will look like or how they will function. However, one aspect of this revolution remains unknown: the extent to which it is affecting people s lives and careers. The challenges of automating various processes will be addressed by Industry 5.0.

Because machines will generate knowledge in the service of humans in Society 5.0, the transition to Industry 5.0 implies a more human-centered approach to design and operation (Carayannis and Campbell 2019). Industry 5.0, in particular, aims to take a more human-centered approach to the design of industrial operating systems. Industry 5.0 builds on Industry 4.0 but expands it through the use of a human-centered approach.

One option is to combine the lightning-fast precision of automation technology with the human-centered design and creativity that are at the heart of your digital transformation journey. The key is to concentrate on the problems that the customer base is trying to solve and to apply the method gradually

Industry 5.0 is defined by a shift away from autonomous robots and toward collaborative robots, which are robots that interact with humans and put them at the center of the process. One of Industry 5.0 s central tenets is that robots will complement, not replace, humans. While Industry 4.0 is primarily concerned with automation, Industry 5.0 will place a greater emphasis on human-machine collaboration.

Digital technologies such as AI or robotics enable radical workplace innovation and optimizing human-machine interaction benefits from the added value that employees bring to the plant. By reintroducing workers to manufacturing, the fifth industrial revolution will unite man and machine to further harness human intelligence and creativity to increase process efficiency through the integration of workflows and intelligent systems.

The next industrial revolution will usher in a new generation of collaborative robots, which already know or will soon learn what to do, thanks to the humanization of robots. Collaborative robots will be intelligent enough to recognize human workers' needs and determine whether they require assistance as the fifth industrial revolution unfolds, as well as to assess risks, consider safety factors, and approach workers safely. The goals of Industry 5.0 are summarised by the International Society of Automation as a humanistic revolution is underway.

Enhancing human productivity is critical for the success of a digital ecosystem that is undergoing a cultural and technological transformation. While Industry 4.0 promises to improve control over the entire product development process, no computing environment is capable of incorporating human factors engineering principles during the early design stage. Manufacturers must increase industrial production flexibility to better protect themselves against disruptions and crises such as COVID-19. As a result, Industry 4.0 overlooks the labor costs associated with process optimization.

References